510 Series

510 Series

Mueller® 510 Series Xtra-Range Full-Seal Pipe Repair Clamps - for 4" through 36" cast iron and steel pipe

- Ductile Iron Finger Lug

- Single and two section styles

- Service outlet option

- 2"-8" 100 psig; 10"-12" cast iron 60 psig; 10"-12" steel 100 psig

IMPORTANT: MUELLER PIPE REPAIR CLAMPS have demonstrated their capability to seal against gas pressures commonly encountered in distribution systems. Smaller diameter clamps of a given design can seal against higher pressures than larger ones. In addition, the pressure that a clamp can contain is effected by the torque applied to the bolts, the uniformity of the bolt tightening (where there is more than one bolt) as well as the type of extent of pipe damage, surface condition of the pipe, environmental conditions and installation workmanship.

Metallic components of repair clamps, including stainless steel, corrode at widely variable rates depending upon many factors, such as installation outdoors or underground, composition of surrounding atmosphere/soil, presence of stray currents, moisture or chemicals, etc. Consequently, repair clamps must be assumed to have a finite service life. Consult with a corrosion professional to determine the life expectancy of this repair clamp taking into consideration all appropriate factors in the application. The piping system designer should determine the suitability of this type product on your particular system. Unforeseen failure of this product could result if these precautions are not taken. Mueller Co. can provide additional material specification information on request by contacting Customer Service: 800-798-3131.

Mueller 510 Series Xtra-Range Full-Seal Pipe Repair Clamps - for 4" through 36" cast iron and steel pipe.

To specify the catalog number, provide the following information:

1. Style number – 510

2. Length – standard lengths can be found on the OD chart on the following page

3. Size number – refer to the OD chart on the following page after verifying pipe OD

4. Catalog number prefix for optional features, if desired.

The catalog number for a 510 Xtra-Range Full-Seal Repair Clamp, 12" long for 6" cast iron pipe is 510-12-0675.

Extra Bolts and Nuts for Mueller Xtra-range Full Seal Repair Clamps:

Clamp Size | Bolt Size | Bolt Part Number | Nut Part Number |

4"-36" | 5/8" x 6" (Standard Bolt) | 533937 | 195236 |

4"-36" | 5/8" x 7" (Starter Bolt) | 533938 | 526655 |

Stainless Steel Bolts:

For optional 304L stainless steel bolts, washers and nuts, add “S-” prefix to clamp catalog number.

Example: S-510-12-0675.

Deep Socket Wrenchs:

Specially designed for use with Mueller Full- Seal Repair Clamps. Long ratchet handle has thumb-tip reverse. Deep sockets (3-1/4") have double hex (12 pt.) and 1/2" square drive.

Part Number | Description |

515207 | 1-1/16" Socket |

515204 | 15-3/4" with 1/2" drive reversible Ratchet Handle |

Bonding Device for Cathodic Protection:

Metallic conductors are set in the gasket to provide contact between the band and the pipe sur- face and are available on all 500 series clamps. These conductors permit electrical current flow by establishing positive contact with pipe and band on each side of the pipe crack or break

To specify optional bonding device for cathodic protection, add a prefix of "2-" to catalog number.

Example: 2-510-12-0675

Add-on feature allows long lengthwise repairs:

The gasket is cemented into the band in an offset position. This allows overlapping the gasket with the band of another clamp when repairing a longer than usual area of pipe. This feature is not available on Servi-Seal style clamps.

To specify optional add-on feature for longer than usual repairs, add a prefix of "1-" to cata- log number.

Example: 1-510-12-0675

MUELLER® 510 SERIES XTRA-RANGE® FULL-SEAL® PIPE REPAIR CLAMPS

Mueller 510 Series Xtra-Range Full-Seal Pipe Repair Clamps – for 4" through 36" cast iron and steel pipe. Standard Lengths: 6", 7-1/2", 9", 10", 12", 15", 18", 20", 24", 30".

Nominal Pipe Size |

Clamp Size Number | Clamp O.D. Range* |

Cast Iron |

Steel | |||

Inches | Millimeters | ||||||

Min. | Max. | Min. | Max. | ||||

4" | 0470 | 4.70 | 5.50 | 119.4 | 139.7 | 50-250,A,B,C,D | - |

6" | 0662 | 6.62 | 7.42 | 168.1 | 188.5 | - | STD |

6" | 0675 | 6.75 | 7.55 | 171.5 | 191.7 | 50-250,A,B,C,D | - |

8" | 0862 | 8.62 | 9.42 | 218.9 | 239.3 | - | STD |

8" | 0888 | 8.88 | 9.68 | 225.6 | 245.8 | 50-250,A,B,C,D | - |

10" | 1072 | 10.72 | 11.72 | 272.3 | 297.7 | - | STD |

10" | 1105 | 11.05 | 12.05 | 280.7 | 306.0 | 50-250,A,B,C,D | 12" O.D. |

12" | 1246 | 12.46 | 13.26 | 316.5 | 336.8 | - | STD |

12" | 1310 | 13.10 | 14.30 | 332.8 | 363.2 | 50-250,A,B,C,D | 14" |

14" | 1433 | 14.33 | 15.13 | 364.0 | 384.3 | - | - |

14" | 1510 | 15.10 | 15.90 | 383.6 | 403.8 | 50-250,A,B,C,D | - |

16" | 1590 | 15.90 | 16.70 | 403.9 | 424.1 | - | 16" |

16" | 1655 | 16.55 | 17.35 | 420.4 | 440.6 | - | - |

16" | 1720 | 17.20 | 18.00 | 436.9 | 457.2 | 50-250,A,B,C,D | - |

18" | 1760 | 17.60 | 18.40 | 447.1 | 467.3 | - | 18" |

18" | 1841 | 18.41 | 19.21 | 467.7 | 487.9 | - | - |

18" | 1922 | 19.22 | 20.02 | 488.2 | 508.5 | 50-250,A,B,C,D | - |

20" | 1990 | 19.90 | 20.70 | 505.5 | 525.7 | - | 20" |

20" | 2070 | 20.70 | 21.50 | 525.8 | 546.1 | - | - |

20" | 2145 | 21.45 | 22.25 | 544.9 | 565.1 | 50-250,A,B,C,D | 22" |

20" | 2220 | 22.20 | 23.00 | 563.9 | 584.2 | - | - |

20" | 2280 | 22.80 | 23.60 | 579.2 | 599.4 | - | - |

24" | 2344 | 23.44 | 24.24 | 595.4 | 615.6 | - | 24" |

24" | 2420 | 24.20 | 25.00 | 614.7 | 635.0 | - | - |

24" | 2490 | 24.90 | 25.70 | 632.5 | 652.7 | - | - |

24" | 2566 | 25.66 | 26.46 | 651.8 | 672.0 | 50-250,A,B,C,D | 26" |

24" | 2672 | 26.72 | 27.52 | 678.7 | 699.0 | - | - |

24" | 2772 | 27.72 | 28.52 | 704.1 | 724.4 | - | 28" |

24" | 2863 | 28.63 | 29.83 | 727.3 | 757.6 | - | - |

24" | 2957 | 29.57 | 30.77 | 751.1 | 781.5 | - | 30" |

30" | 3122 | 31.22 | 32.42 | 793.0 | 823.5 | - | - |

36" | 3786 | 37.86 | 39.16 | 961.6 | 994.7 | - | - |

*Verify pipe O.D. before selecting clamp size.

IMPORTANT: MUELLER PIPE REPAIR CLAMPS have demonstrated their capability to seal against gas pressures commonly encountered in distribution systems. Smaller diameter clamps of a given design can seal against higher pressures than larger ones. In addition, the pressure that a clamp can contain is effected by the torque applied to the bolts, the uniformity of the bolt tightening (where there is more than one bolt) as well as the type of extent of pipe damage, surface condition of the pipe, environmental conditions and installation workmanship.

Metallic components of repair clamps, including stainless steel, corrode at widely variable rates depending upon many factors, such as installation outdoors or underground, composition of surrounding atmosphere/soil, presence of stray currents, moisture or chemicals, etc. Consequently, repair clamps must be assumed to have a finite service life. Consult with a corrosion professional to determine the life expectancy of this repair clamp taking into consideration all appropriate factors in the application. The piping system designer should determine the suitability of this type product on your particular system. Unforeseen failure of this product could result if these precautions are not taken. Mueller Co. can provide additional material specification information on request by contacting Customer Service: 800-798-3131.

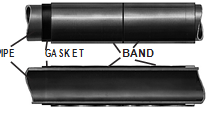

Typical Single Section Full-Seal Clamp - Style Number 510:

Starter Nut:

Standard Bolt & Nut:

Deep Socket Wrenchs:

Bonding Device:

Add-on Feature: