Shur Stop® PE Line Stopping System

Shur Stop® PE Line Stopping System

The revolutionary, lightweight solution providing 100% leak free performance.

![]()

Reliable and easy to use; meets and exceeds ASTM requirements

![]()

Electrofusion Fittings compatible with industry standard universal processors

![]()

Unique mechanical stopper provides NO-BLO performance

![]()

Large machine-to-machine by-pass connections

![]()

125 PSI maximum working pressure to meet demands of modern PE systems

![]()

PE 100 electrofusion fittings work on MD and HD pipe. Also can be fused onto older generation PE pipe per company guidelines

![]()

Size of pipe, compatible with 4”,6”, 8” and 12”

![]()

Sturdy, but lightweight design and construction

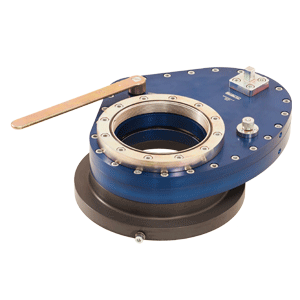

Fittings provide secure reliable electrofusion connection. Installed using proven industry standard processors and procedures.

Lightweight aluminum alloy valve delivers strength and maneuverability in a low-profile design.

Drilling Machine contains built-in travel indicator eliminating guesswork from the drilling procedure. Virtually all PE shavings are collected inside specially designed shell cutters.

Inspection and Cleaning Viewer allows operator to fully insect the pipe after cutting operation

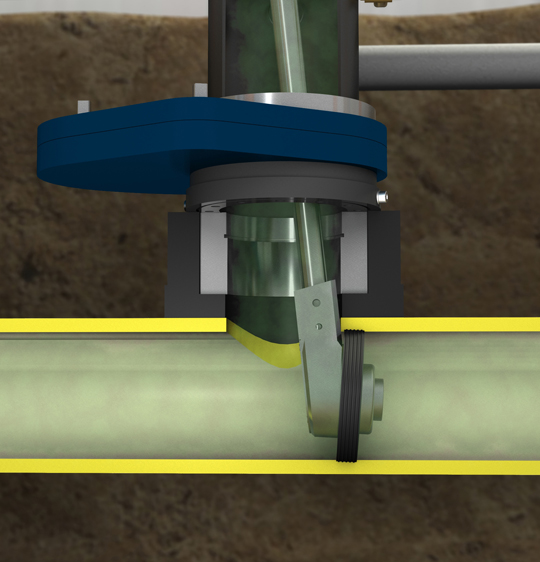

Revolutionary stopper design is mechanically expanded into the pipe wall, ensuring a complete NO-BLO stop-off every time. One stopper diameter covers a wide range of SDR’s, eliminating the need for multiple stopper rings.

UNIT 46 EQUIPMENT

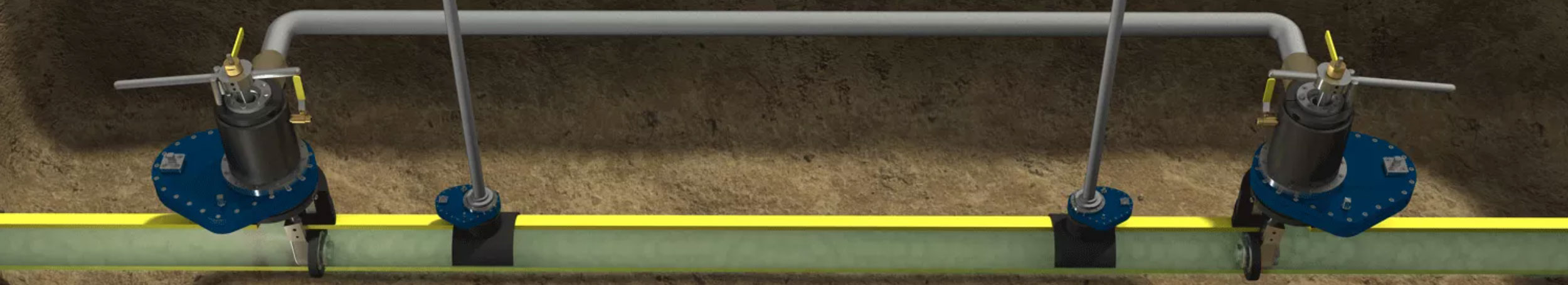

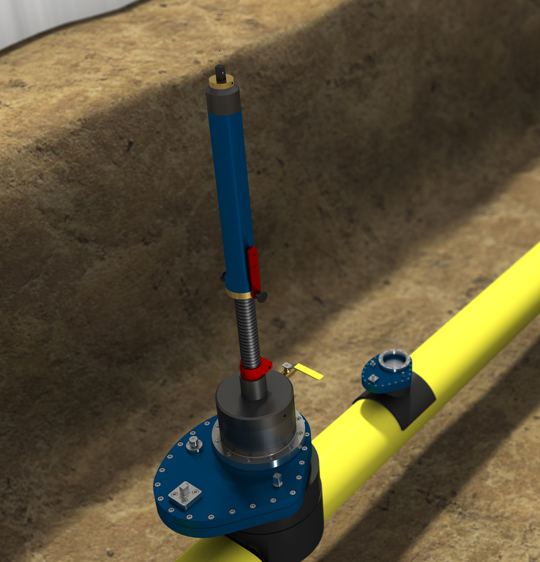

The SHUR STOP® UNIT 46 PE Line Stopping System can be utilized to quickly and efficiently repair, replace or relocate PE pipelines. The equipment is capable of being used in a smaller excavation footprint without need for squeeze offs or double block or bleed processes.

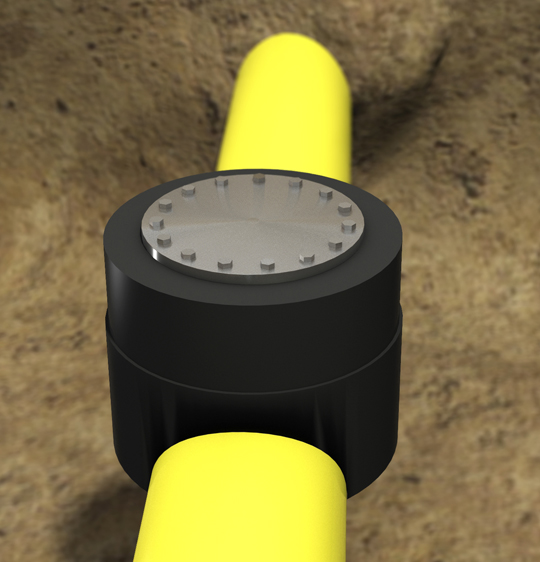

ELECTROFUSION FITTING

- Electrofusion fittings are fully compatible with industry standard universal processors

- O-ring sealed steel completion plug

- Optional urethane protection cap

FITTING CENTERING CLAMP

- Used to properly position electrofusion fitting on pipe for fusion operation

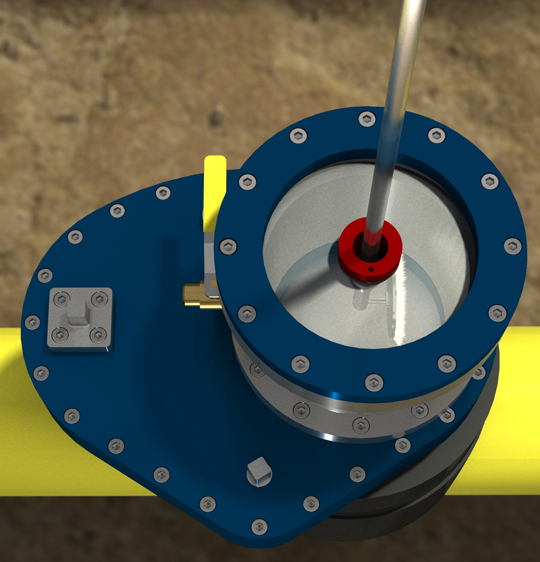

SLIDE GATE VALVE

- 125 psi maximum working pressure at 100˚ F

- 1/4 turn operation

- Equalization valve feature

- Replaceable thread rings

- O-ring seals

DRILLING & COMPLETION MACHINE

- 125 psi maximum working pressure at 100˚ F

- Used in conjunction with Shur Stop® PE 4˝ and 6˝ electrofusion fittings

- Lightweight (18 lbs.) multi multi-functional machine

- Built-in drilling indicator

- Can also be utilized as a completion machine

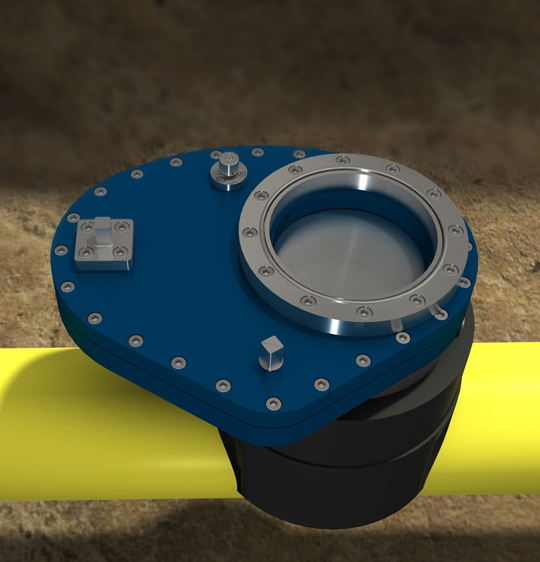

INSPECTION & CLEANING VIEWER

- Used to inspect pipe for debris or shavings before stopping and as a sweeper to remove debris from stopping area

- Large viewing area

STOPPING MACHINE

- 125 psi maximum working pressure at 100°F

- Used to stop stop-off 4” Shur Stop electrofusion fittings

- Body has integral 2” F.I.P. thread by-pass connection

- Used in conjunction with control valve

UNIT 68 & 812 EQUIPMENT

The SHUR STOP® UNIT 68 and 812 PE Line Stopping Systems are lightweight, easy to use stopping systems designed to perform a broad range of pipeline isolation applications on larger diameter PE systems. With similar operation procedures to Unit 46 equipment, operators can be trained on the entire Shur Stop system of sizes quickly and efficiently.

FITTING CENTERING CLAMP

- Used to properly position electrofusion fitting on pipe for fusion operation

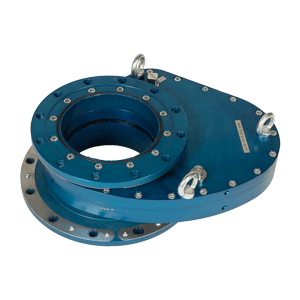

SLIDE GATE VALVE

- 125 psi maximum working pressure at 100˚ F

- Quick 1/4 turn operation

- By-pass valve for easy gate operation

- Low profile design

DRILLING & COMPLETION MACHINE

- 125 psi maximum working pressure at 100° F

- Drilling machine with integrated hydraulic operator

- Built-in drilling indicator

- Can also be utilized as a completion machine

INSPECTION & CLEANING VIEWER

- Large viewing area allows for viewing of cut and interior pipe conditions

STOPPING MACHINE

- 125 psi maximum working pressure at 100˚ F

- Large integral machine-to-machine bypass outlet

- 100 Percent NO-BLO stop off performance